The manufacturer made the decision after finding success with installations in the country.

Rosario, Argentina

Epta Argentina, a subsidiary of Italian OEM Epta Group, will begin to manufacture transcritical CO2 systems in its factory in Rosario, Province of Santa Fe, Argentina this year, following successful implementations of the technology in the South American country.

Epta Argentina currently has 38 transcritical and one subcritical installation in Argentina, with the first being installed in 2014. In one retrofit installation, the company found that the system cut energy system by 25% after one year of operation.

“We had to change myths surrounding the use of CO2,” said Germán Smitt, Director of Refrigeration & Services for Epta Argentina at the ATMOsphere America 2020 conference on October 22. “One of these was the usage of the technology in certain climates, and the other about the design and maintenance of the system,”

ATMOsphere America, organized by shecco, publisher of this website, was held online October 20 and 21 and concluded with a Latin America-focused program in Spanish on October 22.

Proven energy savings

Smitt described a retrofit that was implemented in 2017 in a store in Lincoln, Province of Buenos Aires, Argentina by Epta Argentina with the aim of achieving energy savings and a reduced carbon footprint by using a transcritical CO2system.

The project’s parameters stipulated that it had to be technically viable, in a warm climate, in a developing country, natural refrigerants had to be used in the whole system, and it had to be carried out in a way that there could be a comparison made between energy consumption before and after.

UNIDO (United Nations Industrial Development Organization) and the Argentine Ozone Office took energy measurements for a year before the retrofit took place. In a comparison of energy consumption in 2017 (before the retrofit) and 2018, the installation cut energy by 25%.

Over a 10-year period, the system projected a 10% reduction in energy consumption, along with a 90% reduction in total equivalent warming impact, going from 2,754 to 267 metric tons of CO2e.

The project was initiated from a joint bid request by UNIDO and the Argentine Ozone Office. The main objectives in the request were that the project be replicable and create confidence in this type of installation and technology.

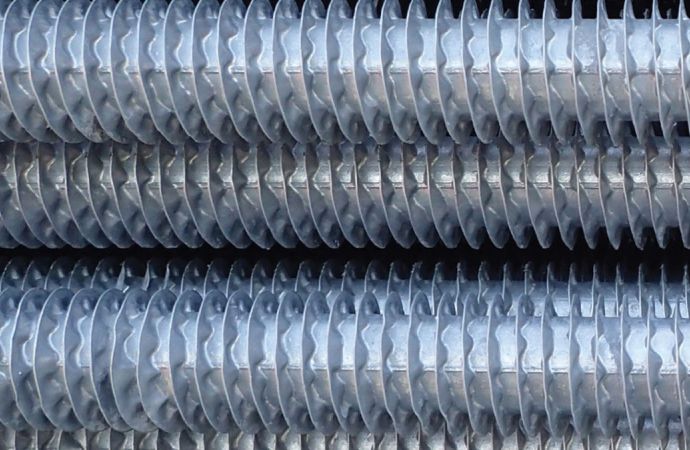

The sales floor measures 1,300m2 (13.993ft2), requiring 69kW (19.61TR) for medium temperature and 9.53kW (2.71TR) for low temperature. To meet this, the retailer installed a transcritical system with two compressors for low temperatures, two for medium temperatures, and one in parallel, and a subcooler chiller system

The subcooling technology is comprised of a chiller linked to a heat exchanger installed after the gas cooler. In order to comply with the parameter of only using natural refrigerants, the chiller here utilizes propane (R290).

We had to change myths surrounding the use of CO2."

– Germán Smitt, Epta Argentina

Related stories