The complex installation met Comersur’s refrigeration requirements, including heat recovery.

Santiago, Chile

A transcritical CO2 (R744) installation that went live last July for Comersur, a fresh and frozen food processing company in Santiago, Chile, has resulted in US$194,000 a year in electrical energy savings. It is also is projected to save US$20,000 in natural gas used for heating water.

The savings is based on a comparison to the an installation done with the latest technology using R507.

This data was shared by Luca (Pier) Zecchetto, CEO of Chilean refrigeration provider pórtan, information during a session at ATMOsphere America’s Latin America-focused program in Spanish on October 22. (The online conference was organized by shecco, publisher of this website.)

In assessing the systems’ energy performance, pórtan, the first company to design and install transcritical systems in Chile, carried out its own research using installations in the city of Santiago, said Zecchetto.

Compared to an old, traditional R507 installation, the transcritical system consumed around 64% less energy. Compared to a latest-generation R507 installation with an electronic inverter, it consumed about 44% less. And when compared to a typical transcritical CO2 installation with parallel compression and adiabatic gas cooler, but without multi ejectors – as this installation has – it consumed about 7% less energy.

In addition to the energy savings, the CO2 system avoids a tremendous amount of direct CO2 emissions by using R744 (GWP of one) rather than R507 (GWP of 3,985), noted Zecchetto.

List of requests

As a producer of baked goods and prepared meals, Comersur firsts cooks its products before cooling them. Thus, Comersur “had many specific requests, making it a complex installation,” said Zecchetto.

For instance, Comersur requires working temperatures ranging from -20℃ to 90℃ (-4℉ to 194℉), with evaporation temperatures of 5℃ (41℉), -1℃ (30.2℉), -8℃ (17.6℉), -30℃ (-22℉), and -42℃ (-43.6℉). Comersur also wanted to use only one category A1 refrigerant (nonflammable, non-toxic, not explosive) with the lowest GWP possible in the whole system.

Taking into consideration the water scarcity in Santiago, another requirement was to minimize water usage in refrigeration-related processes. This includes recovering heat for 4,000l (1,056.7gal)/hr of water at 60℃ (140℉) in six production lines producing 8,000kg (17,634lbs)/hr of finished food products.

While Comersur considered R507 for the project, it had installed a subcritical CO2 system in 2015 and was happy with its efficiency, pushing the company toward using CO2 again.

Comersur also wanted the system to be energy efficient with a capacity of 50kW (14.2TR) to 1,800kW (512TR) of refrigeration to meet the requirements of its processes.

All products arriving at the facility are fresh, requiring temperatures of 0-3℃ (32-37.4℉). They are then cooked in different phases in refrigerated production areas with room temperatures of 12-15℃ (53.6-59℉).

The food then goes into the six production lines where blast chillers take the products from 90℃ to 30℃ (194℉ to 86℉), from 30℃ to 0℃ (86℉ to 32℉), and from 30℃ to -20℃ (86℉ to -4℉).

The finished products can go to a refrigerated packaging area at 5-10℃ (41℉-50℉), a freezing chamber at -20℃ (-4℉), or a storage chamber at 0℃ (32℉), and finally to a shipping area refrigerated at 3-5℃ (37.4-41℉).

A complex installation

In Santiago, temperatures can reach 39℃ (102.2℉) and six months out of the year the average temperature is above 33℃ (91.4℉). During these same months, the relative humidity does not go above 45% (a low figure).

Zecchetto explained that this climate was taken into account when choosing a central booster system with parallel compression, adiabatic gas cooler, high pressure multi-ejectors, and heat recovery.

The main compressors have electrical motors with permanent magnets, making them 10-14% more efficient, as well as a control system that allows for 15-100% capacity control, which, according to Zecchetto, is good for variable charges.

The medium temperature compressors are supported by inverter technology.

Adiabatic gas coolers take advantage of the high temperatures and low relative humidity of the local climate allowing for a difference of 5-6℃ (9-10.9℉) between ambient temperatures and the temperature of the air that enters the gas cooler.

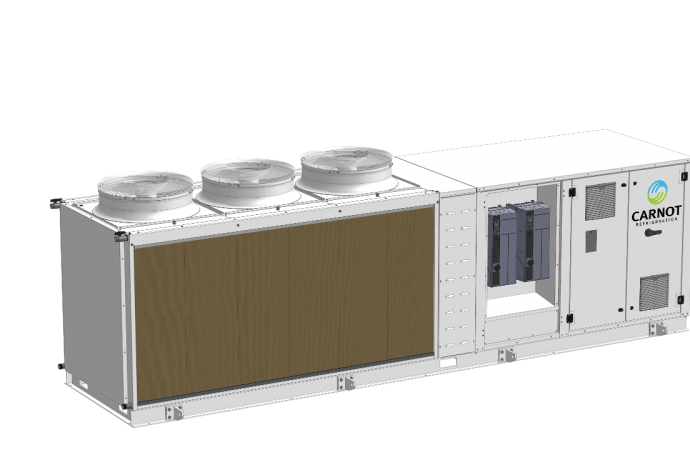

pórtan chose the equipment specifications together with SCM Frigo, an Italian CO2 refrigeration manufacturer (and a subsidiary of Swedish manufacturer Beijer Ref), which manufactured the equipment.

The transcritical R744 installation consists of two identical racks, each with a capacity of 900kW (256TR), in an indoor machine room with total power of 1.8mW.

Each rack has one Danfoss vapor ejector; an intercooler for the cooling of the discharge gases from the low-temperature compressors, and two gas coolers for the discharge from the parallel compressors and the medium-temperature compressors.

Each rack also contains:

- Five Bitzer medium-temperature compressors of 270kW (76.8TR), supporting an evaporating temperature of -7℃ (19.4℉) and gas cooler outlet temperature of 39℃ (102.2℉).

- Three low-temperature Bitzer compressors of 320kW (91TR), supporting an evaporating temperature of -42℃ (-43.6℉) and condensing temperature of -7℃ (19.4℉).

- Three low-temperature Bitzer compressors of 450kW (128TR), supporting an evaporating temperature of -30℃ (-22℉) and condensing temperature of -7℃ (19.4℉).

- Four parallel Bitzer compressors of 400kW (114TR), supporting an evaporating temperature of 5℃ (41℉) and gas cooler outlet temperature of 39℃ (102.2℉)

pórtan together with Nuova Service, a local installation and commission company, installed the equipment.

Cold is transmitted throughout the facility via 10 matrix lines in high-pressure copper tubing. The aspiration lines range from 5.08cm (2in) to 2.86cm (1.13in) in diameter, and the liquid lines range from 4.13cm (1.63in) to 2.22cm (0.88in) in diameter.

Comersur’s goal is to focus on its main business, so it has hired Nuova Service to maintain and optimize the system.

Part of the installation is a sophisticated oil control system that allows control of oil levels and/or pressure, requiring only a minimal amount of oil to be used, in this case less than 50l (13.21gal).

The electronic control system itself is duplicated to provide backup, as R744 systems cannot function without the electronic components. Added to this is a telemetry system, which controls and monitors pressure and allows for energy consumption management.

According to Zecchetto, the project is meant to be safe, sustainable, and efficient while taking into account the local climate, the food processes being carried out, and the everyday use of the systems.

As an added feature, the installation does not require fresh or treated water.

Related stories