The Hillphoenix system is in line to deliver a four-year return on investment at distribution center, exceeding original projections.

Medellín, Colombia

A transcritical CO2 (R744) system installed last year at an existing distribution center in Rionegro, Antioquia, Colombia, South America (near Medellín), has so far reduced energy consumption by 45% compared to a new conventional fluorinated system, according to the equipment distributor for Columbia, which installed the system.

Given this savings, and lower maintenance costs, the transcritical CO2 system’s manufacturer ,Hillphoenix, estimates a four-year return on investment (ROI) for the premium paid for the CO2 system over the conventional system, said Mauricio Baena, Sales Manager Industrial South America, Dover Food Retail, owners of Hillphoenix.

He shared this information during a session at ATMOsphere America’s Latin America-focused program in Spanish on October 22. (The online conference was organized by shecco, publisher of this website. The transcritical system had been in operation for seven months by that point.

Hillphoenix had originally projected 35% reduction in energy consumption, and a seven-year ROI, he said.

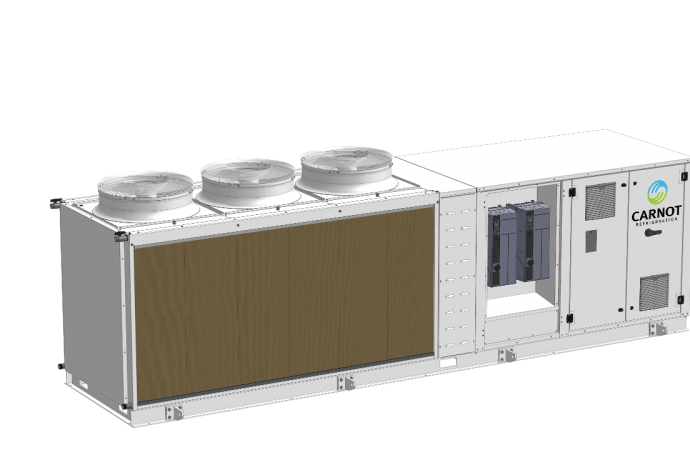

The parallel compression transcritical system with (dry) gas cooler which delivers 240TR (844kW) of cooling capacity, was “twice as expensive as a conventional system," said Baena. Because it was the first transcritical installation for the warehouse, steel tubing was required, causing the mechanical materials to be 134% more expensive. And due to the higher electrical technology costs in the region, the controls were 25% more expensive.

Initial reservations

The owners of the warehouse, which mostly processes and stores imported food products from Europe, initially had some reservations about installing a natural refrigerant system.

“It was a challenge to explain that CO2 has special requirements because of pressure, but that technicians’ knowledge can be molded to handle CO2,” said Baena.

According to Baena, there were other advantages specific to the transcritical system that helped Hillphoenix secure the contract. These include the system’s “ability to create hot water for the warehouse’s processing services and CO2’s ability to quickly cool products as they arrive,” he said.

Another plus was that future Colombian policy changes could have forced the warehouse to undergo a retrofit if an HFC system had been installed.

The warehouse and food processing facility has 2,000m2 (21,528ft2) of refrigerated space with two temperature groups, including six cold rooms for frozen products (one bi-temperature), six processing rooms, six antechambers, and three loading docks.

Related stories