Howe’s 1,000lbs/day unit is being used by Raley’s store in California.

Howe CO2 ice machine with storage bins

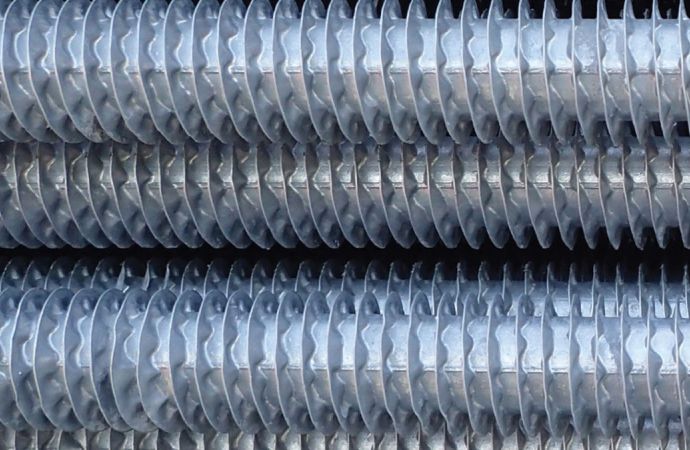

Howe Corp., a Chicago, Illinois (U.S.)-based manufacturer of flake ice machines, has developed a new CO2 (R744) recirculated ice system that has been installed at a Raley’s supermarket in Sacramento, California (U.S.)

The Raley’s store, which uses an ammonia/CO2 refrigeration system, employs the Howe machine to produce up to 1,000lbs (454kg) of flaked ice daily. The ice machine is cooled by recirculated liquid CO2 as if it were a low-temperature display case, and operates at evaporator temperatures between -10°F and -20°F (-23°C and -29°C), noted David Barrent, Vice President, Engineering & Operations, for Howe.

Howe also offers a direct expansion (DX) version of the 1,000lbs/day CO2 ice machine, with an evaporator temperature of 0°F (-18°C). In addition, the company makes machines that produce 2,000lbs (908kg)/day and 4,000lbs (1,816kg)/day of flaked ice, in DX and recirculated configurations.

The major difference between Howe’s ice machine and a low-temperature display case is that, while in operation, “our load is constant and not cycling on/off based on case temperature setpoint,” explained Barrent.

Howe’s DX systems address the constant load by utilizing electronic expansion and evaporator pressure-regulating valves to control the refrigeration parameters. However, the constant-load requirement creates “some challenges” for Howe’s recirculated systems, Barrent said. In response, Howe has developed, for its newest 1,000 lbs/day CO2 recirculated machine, a “load-matching scheme” that uses an electronic valve to ensure “proper operation of our constant-load ice machine.”

Howe’s 2,000lbs/day and 4,000lbs/day recirculated CO2 machines do not utilize the load-matching technology, “but we are exploring adding that to our offering,” said Barrent.

85 units sold

Since introducing its CO2 ice machines in 2009, Howe has sold 85 units in the U.S. and Canada, Barrent said. Supermarkets typically use the machines to produce ice for seafood and produce merchandising and displays, as well as “spot displays around the store for various products,” he noted.

CO2 flake ice machines take advantage of the “efficiency of the [CO2] refrigeration rack system” to which they are attached, said Barrent. He noted that unlike HFC or HFO ice machines, he is not aware of any self-contained CO2 machines that operate independently of a rack system. However, Howe is working with vendors to procure a line of CO2 condensing units sized for its ice makers “to provide more options for our customers looking for natural refrigerants.”

For industrial customers, Howe offers a line of large stand-alone ice machines that use HFC/HFO or ammonia as refrigerants and produce between 6,000lbs (2,722kg)/day and 20,000lbs (9,072kg)/day of flaked ice. The company does not currently offer CO2 machines for industrial applications, but it looking into developing new CO2 evaporator designs for interested customers, said Barrent.

Our [ice machine] load is constant and not cycling on/off."

– David Barrent, Howe

Related stories