Greencold has installed a CO2-based plant with a cooling capacity of 180 kW at a UK food-processing firm.

Six low temperature blasy chillers at the installation.

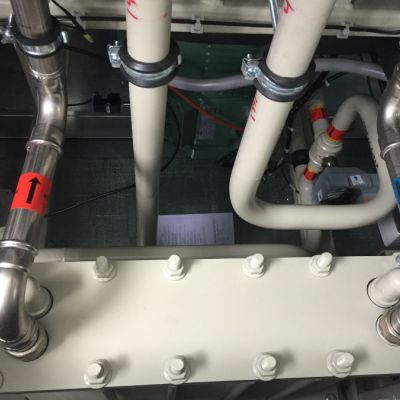

Greencold has installed a new CO2-based cooling plant at a food-processing firm in the United Kingdom. The plant, which has a cooling capacity of 180 kW, comprises six identical cooling chambers for low-temperature blast chilling of meat down to -20° C.

For the end user, the choice of CO2 was motivated by price and the desire for future-proof technology, according to Greencold.

The customer initially considered an ammonia-based pumped recirculation system. But this was subsequently ruled out due to price, space, delivery time and specific site safety considerations.

Another option would have been to use a direct expansion system with HFC R407F, but the end user ruled this out amid the HFC phasedown, rising refrigerant prices and the mass of the refrigerant required.

A pumped system with CO2 was also considered, but again this was ruled out due to the significantly higher cost of including the required low-pressure station vessel and skid. Space was also lacking for such a system.

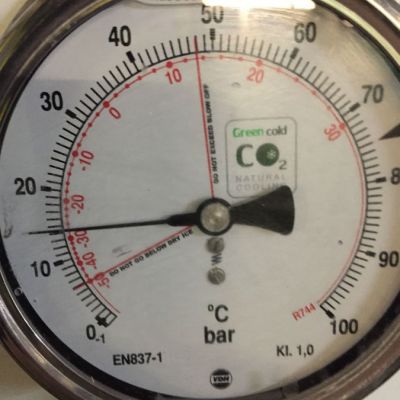

The system chosen is a direct expansion system with approximately 300 kg of CO2. The freezer suction line pressure is typically around 15 bar and the average freezer liquid line pressure is approximately 25 bar.

GALLERY

Related stories

_1613679989.jpg)